|

|

| Nose Wheel

Well |

|

|

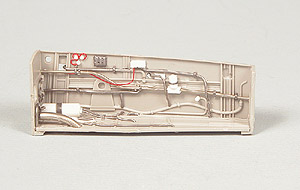

The

nosewheel well area is going to

need a lot of work. Detail is lacking and in many cases, inaccurate.

Fortunately, the nosewheel well comes in five pieces so it will be easy

to detail. Solder, wire, styrene rod, strip and sheet and lead foil rounded out the

necessary materials. Because of the way they are constructed, the mainwheel wells

will have to be detailed once they are put together. They are worse than

the nosewheel so I will pretty much wipe them slick and completely redo

them. More on them later. |

Click on thumbnails to enlarge |

|

|

|

|

|

Nose Strut |

|

|

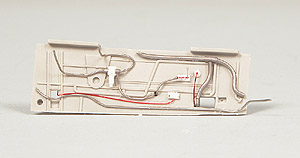

As I

previously mentioned , this is going to be a very heavy model. The

instructions call for 110 grams (3.88 oz.) of weight in the nose to

offset the tail. I think this is perhaps conservative so I will add

about 25% more above that just to be on the safe side. Subsequently,

there is going to be a lot of stress on the nose strut to support all

this weight. I got white metal main struts but could not find a metal

nose strut. I know there are some currently available but when I got the

metal ones two years ago they were not so I do not see the sense in

getting a whole new set just for the nose strut. To that end, I am going to beef up the kit pieces with

steel pins. I have a supply (though dwindling, admittedly) of

0.030" steel pins from an old contour gauge that are perfect for the

job. I first CA'd a piece of 0.125 x 0.25" styrene block (Fig. 1)

in two places to the outside of the nosewheel well sides to serve as a reinforcing

block. Overkill perhaps, but it will be more than adequately strong. It

is much better to err on the side of caution. I ground a channel into

the nose strut halves using a 0.033" carbide drill bit (Fig 2) and

bent a piece of the 0.030"wire to fit inside of it. I used liberal

amounts of CA to affix it in place and then ground any bits protruding above the channel

flush with a Dremel cut-off wheel. This will significantly

strengthen this strut at it's weakest point. Likewise, I reinforced all

attachment points for the other nose strut pieces with steel pins where they

will insert through holes drilled in the styrene reinforcing

blocks. I did not have handy any metal rod or tube of appropriate size

for the inside of the strut so I did the next best thing; I strengthened

a piece of 0.080" styrene rod with a steel pin and inserted that

into the strut (fig. 3, lower right). The pin extends past the styrene

to mate with the top half of the strut, adding rigidity to the entire

structure. This little project was good for close to two hours worth of

work however the benefits gained far outweigh the time required. This

strut will not break or deform under load for any foreseeable amount of

time. |

Click on thumbnails to enlarge

Fig. 1 |

Fig 2 |

Fig. 3 |

|

|

|

|

| Radome |

|

|

Trumpeter,

like pretty much everyone that has ever produced a THUD kit, got

the contours of the radome off by a good amount. When placed against a

scaled up photo of the real thing, the kit piece is too long

and way too "pointy". There is a definite curve to the tip of

it. The kit piece looks like something that should be

on the front of a Delta Dagger instead of a Thunderchief. I used the razor saw and cut off the top

4mm or so and reshaped it using the Dremel and a grinding bit, files and

sandpaper. Fortunately the tip of the radome was of sufficiently

thick plastic that I did not have to add any styrene, just some CA at

the very tip. The difference is very noticeable. The tail and rudder

have some pretty sizeable shape issues as well and will have to be dealt

with in time. That is going to be a considerably bigger undertaking than

the radome! |

Click on thumbnails to enlarge

|

|

|

| Canopy and

Windscreen |

|

|

I am not

following any specific order as this time, just whatever interests me at

the time. Like the rest of the kit, the clear parts are very large.

Quality is not as good as I would expect from a kit in this price range

but it's acceptable. Areas of the canopy and

windscreen that would be occupied by framework are lightly frosted,

which makes it easier to distinguish demarcation lines. The windscreen

had a scratch that ran along the inside of it so I had to polish it out,

no biggie. As soon as I removed the

canopy from the sprues I noticed something that I have never seen in all

my years of modeling.....THERE WERE FINGERPRINTS ON THE CLEAR PART! I

was floored. Fortunately the oils and acids on that person's fingers had

not etched into the plastic. I cleaned them off with detergent and water

and coated them with Future™. Both the canopy and windscreen were

totally void of any details. Since there was a fair amount of structure

on both, the canopy especially, I constructed it from reference photos

using styrene, solder, wire and soda can aluminum. All in all I added

about 40 pieces to the canopy. I added a control box and wet compass to

the windscreen along with a few bits of styrene for framing details. I

will insert a Waldron instrument in the wet compass when it's been

painted. |

|

|

|

|

|

|

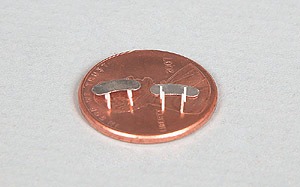

The kit did not

come with any mirrors for the front canopy bow (there are two) so I cut

some out of soda can aluminum, removed the paint on one side (leaving

the plastic coating on the other because CA adheres to it a lot better

than to the bare metal), with 0000 steel wool and then polished it with

the Dremel and some Turtle Wax Clearcoat polish. I may glue some

aluminum foil onto them after they are painted as that will give as

close to a mirror finish as you can get. Polished aluminum is pretty

shiny but aluminum foil is better. I made the attachment points out

of some 0.010" x 0.020" styrene strip. They will be

attached to the windscreen right before it is installed because they are

very fragile! |

|

|

Drag

Chute Compartment |

|

I found several

photos of THUDS sitting on the ramp or in revetments with their drag

chute doors open so I decided to leave mine open too. If nothing else it

adds a little bit of interest to the tail section. Trumpeter allows the

option and does a pretty decent job doing the door. Where they fell

short, by a country mile short, is they did not close off the

bay. If you leave it open you will be looking at the top of the engine,

which simply did not happen. No way you could lay a nylon parachute on

top of the afterburning section of an engine. I used a contour gauge to

get the shape of the interior and built a box to go around the opening.

I only had one photo of the insides of it so I did the best I could.

Raised rivets were made by turning the styrene over and running a ponce

wheel over it to make raised impressions. Simple but effective. When

all is said and finished, the improvement was well worth the effort. |

|

|

|

|

|

At

this point I have joined the fuselage halves. Fit between the halves

for the most part was very good. Not a lot of seam cleanup is going to

be required. A fair amount of touch-up rescribing will be required

because this model has a lot of panel lines. Next up is to address the

incorrect shape of the vertical tail. |

|

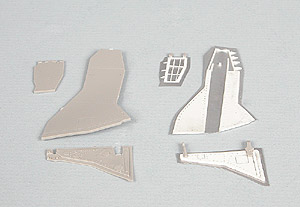

Much has been

said about the shape of the Trumpeter tail. Before I took the razor saw

to it I searched the web for a good while to find a photo of a THUD from

an exact side plan form view. I finally found one. I photographed the

kit tail, still on the sprue (though I taped the rudder in place) and

cut it out in Photoshop. I outlined it with a fine black line and

increased it's transparency. I then superimposed it over the photo of

the real thing. I immediately noticed that the kit tail was too tall and

that the ECM fairings were in the wrong place. Any slight differences in shot angle of the two photos would not

account for the height and location differences. Lowering the top of the

tail will be a pretty easy task. Moving the ECM antenna fairings are going to take a lot more work. The first thing I did was to cut out

the four ECM fairings with a #80 carbide drill bit in my battery

operated Dremel (because it turns at a slower speed than the lowest

setting on my AC one), using great care not

to break it. They are so sharp that they really work the best for

cutting out small parts. I then cut pieces of 0.030" thick styrene sheet

using the holes as templates and filled them in, using CA to fill any gaps. The pieces

were then sanded

smooth with files and sandpaper and polished with 0000 steel wool. Next

up was to take the razor saw and remove the top .18' or so from the tail

and reshape the top contour to match the photo. The thin black

line in the photo at right delineates the new top of the left piece compared to the original

right piece. From a distance you can see how much of a difference there

is. The top of the fin was filled with CA and the ECM antenna fairings

replaced in their correct locations. |

|

|

|

|

| With the tail

modifications finally completed, it becomes apparent how far off the kit pieces

were, the lower antenna especially.

Was it worth 4 hours of work to correct it? Most

people might say no but I figured if I am going to correct

other glaring errors in this model (the radome and drag chute

compartment to name two) I may as well do all of them. I know there

is a resin replacement for this fin but why plunk down a bunch of money

for someone else's work when I can do it myself and get the same

results? |

|

|

|

Combat

Camera |

| The kit includes

the fairing just behind the radome for the combat camera but once again

there is nothing inside, leaving yet another Trumpeter signature black

hole. I constructed a box out of sheet styrene and made a lens out of

styrene tube and clear sprue. In this scale it would be noticeable that

there is nothing behind the "glass". |

|

|

|

At

this point it is time to attach the wings to the fuselage. I plan on

leaving the flaps and slats down but will probably just glue them in

place. The hinges included in the kit do not appear to be very strong.

Once the wings are on I can start detailing the main wheel wells. |

|

|

Wings |

|

Before

I could start putting the wings together I had to accomplish several

tasks. First off was to fill in several very large (0.20") ejector

pin marks in the intakes. 500 pound bombs don't make holes that big and

I should know, I have dropped my fair share of them. One was actually

raised for half of it and sunk for the other half. This is totally

unacceptable for a kit of any price, much less one that costs a

C-note or more. Additionally, there is a rather pronounced (0.050")

step on the fuselage intake area that lies barely 1/2" inside the

intake. Granted, I may not have any photos of the inside of a THUD

intake but I would be willing to bet my next paycheck that this step is

not there in the real thing. And they would be very visible in the

completed model if not corrected. The easy way out would be just to make

FOD covers for the intakes but I want them open. I took the Dremel and a

grinding bit and ground away the step, tapering it to a knife edge so it

would not be noticeable once the wings are in place. When the wings and

fuselage are joined it will give the impression of a continuous surface. |

|

|

|

|

Wing

construction was fairly straightforward, to a point. Trumpeter provided

two separate sprues for the port and starboard wings. (Western?) logic

would dictate that ailerons, flaps, slats and spoilers on one sprue

would mate with the corresponding wing halves on that sprue. As

the inimitable John Belushi (aka "Bluto" from Animal House) would have said

"But nooooooo!". Ailerons, flaps, slats and spoilers

for one wing are found on the sprue for the other wing and vice

versa. I am still shaking my head in bewilderment over that one.

It left me wondering what Confucius would have had to say about that

one; perhaps "Sum Ting Wong!". They do provide

some metal rods and PE parts so you can make the flaps and slats

positionable. At a quick glance, they did not appear to me to be

particularly substantial and I was right. Mounting the flaps was

straightforward, however trying to mount the slats was an exercise in

utter frustration. I finally glued the wings together without them and

will mount the slats once everything is dry and I clean up the awful seam

that runs down the area directly behind it. The kit also provides separate

spoilers so they can be positioned either up or down. The only time

spoilers would be extended is if the aircraft were on rollout (to

shorten landing distance) or maintenance was being performed on them.

Therefore I decided to display them in the stowed position. The fit was

less than perfect, a seemingly all too frequent occurrence with this model,

necessitating that each piece be individually fitted. Another

unnecessary time waster. There was also a pretty nasty seam on the

inside of the intake when the wings were joined but some filling with CA

and filing and sanding . The fact that the area is easily

accessible before the wings are joined to the fuselage made this an easy

task. |

|

|

Main

Wheel Wells |

|

The

detail in the mainwheel wells is, to put it tactfully, well.....awful.

It is fictitious in most places and very sparse to non-existent in

others. As you can see from the photos at right, Trumpeter's rendition

falls woefully short of the mark. They also leave a black hole in

the wheel wheel where that grayish electric motor (which they also left

out) is in the photo so that will also have to be corrected with a

bulkhead. THUD wheel wells, like most modern jets, are a pretty busy

places filled with wires, cables, actuators, hydraulic and oil lines,

etc. I did not take me more than a millisecond's worth of pondering that

there really was nothing in these wheel wells worth saving so I took the

Dremel and a grinding bit and wiped everything slick. I will just go

ahead and scratch build all of it. I do believe someone makes a set of

resin wheel well inserts for this model. Unless you are a glutton for

scratchbuilding punishment like I am, I would strongly suggest you

invest in them. In this scale, there is no excuse for the really weak

representation presented by these wheel wells. The scratchbuilt wheel

wells are constructed of wire, solder, soda can aluminum, stainless

steel screening, lead foil, styrene sheet, rod, tube and strip. I added

a soda can insert to one side of the wheel well so I could add raised

rivets. It is easy to work and if you glue the side that has the plastic

liner to the styrene it adheres very tightly with some CA. It took about

14 hours to complete this one well but the finished results were

definitely worth the effort. |

The Real Thing

|

|

Trumpeter's rendition

|

|

Completely

reworked

|

|

|

|

|

|

|

|

|

|

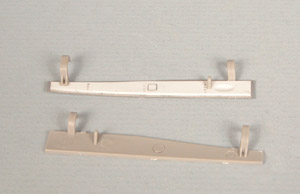

Main

Landing

Gear Doors |

|

The landing gear

doors are going to also need to be re-done. They are very thick and, in

the case of the main doors, totally void of detail. Since I was working

from essentially nothing, good planning was a must. I traced the kit

piece onto a piece of 3" x 5" index card and then drew in all

the detail. I then cut out the pieces of the card and traced them onto

the sheet styrene with a pencil and cut them out with a fresh #11 blade.

I also used the kit

pieces as templates and cut out new pieces from soda can aluminum. The

only thing I will save from the kit doors are the hinges. I added

styrene sheet to the aluminum to build up the center parts of the doors.

As the

photos at right show, the difference is quite noticeable. Once again,

for an aircraft in this scale, Trumpeter should have done a considerably

better job than they did. |

|

|

|

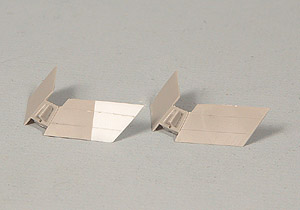

Nose

Landing

Gear Doors |

|

As

bad as the main landing gear doors were, they did not even approach the

nose gear doors. I got irritated at the main doors, I got downright furious

at the nose doors. Not only were they very thick and totally lacking in

detail, they were covered in four nasty ejector pin marks. I have

seen 1/72 and even 1/144 parts that were far better done this. For 1/32

it's totally unacceptable. Once again I traced the outline onto soda can

aluminum and added sheet styrene to form the inner body of the door.

Like the mains, I kept the kit hinges but that was it. The rest are

destined for the trash where they belong. |

|

|

|

Odds

and Ends |

|

There are a few

other things that need attention before I start on the external stores

and ordnance. First up was the doors for the inflight refueling probe. Like all the other doors

in this kit, they were extremely thick and completely devoid of detail. I

once again

traced the outline of the door on soda can aluminum and cut out some

sheet styrene for the center of the door. I used a file to make a groove

down the middle of the door where it will mate with the probe. There is

a second door, forward of the main one, that closed after the probe was

extended. All that needed to be done on that one was thin the edge that

would be visible, no point in doing more work than is necessary. |

|

|

|

Jets have numerous

drains along the underside of the fuselage, especially around the

engine. Using reference photos, I drilled several 0.027" holes and

inserted pieces of 0.025" rod with a 0.0135" hole drilled in

the end. The fuel dump mast had a basically solid end to it so I drilled

it out and inserted four pieces of 0.010" wire through the side of

it. Sometimes it's the little details! |

|

|

|

There is a large

vent on the port side of the fuselage just below and aft of the inflight

refueling probe bay. In the model it is simply depicted as an oval

depression. On the real thing there is a definite hole there. I ground

out the oval with a Dremel and grinding bit and inserted a piece of

styrene tube into the hole. I thinned the edges to near scale thickness

with a round file. I also ground out the cooling slots in the door

covering the M-61 20mm Gatling gun with a 0.020" carbide drill

bit. As you can see from this photo, there is a gap between the

resin coaming and the kit piece. I filled it in with some strip styrene

as it will be noticeable. |

|

|

|

External

Stores and Ordnance |

|

The first thing I

noticed when I started looking at the external fuel tanks and armament

was part of one of the drop tank fins had been torn in half. It was not

in the bag so I had to fix it with some styrene sheet. Unlike so many

models that depict fins on drop tanks as thick, rectangular cross

section slabs, Trumpeter actually made these very thin and tapered, a

nice touch. I cut off the bad part of the fin with a Dremel circular saw

and added a piece of 0.025" styrene sheet, adding the taper with a

Dremel shaping bit and files. A little bit of rescribing and all fixed!

The rest of the drops went together well but a fair amount of filling

with CA was required where these fin sections fit into the tank

itself.

I made up six M117 750lb GP bombs and two Mk82 500 lb

GP bombs. The fuses supplied with the kit were somewhat crude so I

reworked them, adding some soda can aluminum to simulate the spinner

blades.

|

|

|

|

General

Construction |

|

For the most part

the kit went together reasonably well. Fit was excellent in places and

pretty poor in others. The windscreen fit rather poorly, requiring a lot

of filling, filing and sanding. Trumpeter's system for attaching the

slats was totally inadequate. In addition to being very weak, it was

also very inaccurate. Trumpeter's system for the flaps and slats was

fragile, and in the case of the slats, fictional. I decided to just glue

them in place in the up position. I drilled holes in the top

of the metal landing gear and inserted a 0.030" steel pin. I then

drilled a hole all the way through the wing where the strut was

attached. I cut off the pin and grounded the area flush with the wing.

The struts themselves were affixed with a liberal amount of CA and the

pin added a good bit of rigidity. I don't anticipate any problems with

either the main or nose gears. |

|

|

Painting |

|

I sprayed the model

and the myriad number of free parts with automotive primer out of a rattle can. The sheer

size of this model pretty much makes this a necessity. I painted the

model in the standard four color SEA (Southeast Asia) pattern of FS

36622 camouflage gray) for the undersides and FS30219 (tan), FS34079

(dark green) and FS34102 (medium green) for the upper surfaces. Bombs

were painted FS34079. Painting something this large was quite an

undertaking; the process took me about five hours to complete. Once the

enamels were dry I sprayed the model with two coats of Future™ to

prepare it for decaling. |

|

| |

|

Decaling |

|

The decals

supplied with the kit are designed by Two Bobs and printed by

MicroScale. They are gorgeous so I saw no need to look elsewhere or make

any for myself on the ALPs. They went down very easily and once dry the

carrier film was all but non-detectable it was so thin. |

|

|

| |

|

This build was profiled in FineScale Modeler Magazine. |

|